Email Questions to : stewart@maplewoodbicycle.com

_______________________________________________________________________________________________________________________

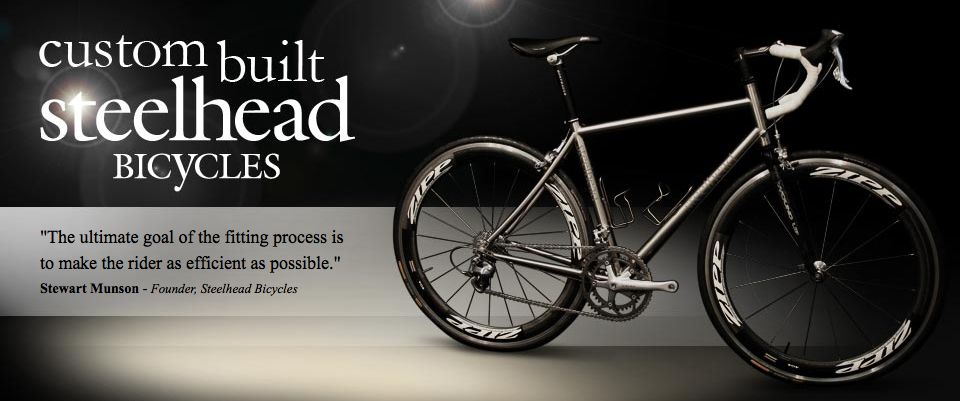

What makes Steelhead Bicycles different?

Steelhead’s philosophy on road geometry is based on thousands of professional fittings performed at their retail store, Maplewood Bicycle, in St Louis, Missouri. The ultimate goal of the fitting process is to make the rider as efficient as possible, just like a hybrid vehicle. The less energy the rider expends to maintain a given speed the better. With that efficiency we must also focus on comfort. What fun is it to ride if after the ride you hit the medicine cabinet for Ibuprofen for the stiff lower back and burning neck and shoulder muscles? The bike fit is critical to eliminating sore or numb hands, numb or chaffed genitalia, sore knees, etc. It is possible to ride pain free, all it takes is a specialist who truly can establish your fit within your range of motion and limiting factors of flexibility and injuries.

With that said, over a decade ago our founder, Stewart Munson, noticed the trend that each client was needing a taller head tube length on their custom bikes than that of the regular production geometries on the market. Most of our Steelhead clients are not elite racers and do not get massage and flexibility training on a daily basis. Most of our client’s are stuck in front of the computer at work all day and carry their stress in their shoulders and neck. That specific decrease in flexibility directly correlates into reduced ability to reach out and down to the bars. Therefore we slightly reduced the effective top tube length as well. Now you can keep your hands on the brake and shift lever hoods where they should be. If you want to hammer and chase down your Sunday morning training buddies, go ahead and reach to drops, Hey, what do you know, you can use those things comfortably too.

To keep the bike well balanced and stable with the slightly higher center of gravity our production framesets have slightly longer chainstays to keep the weight bias where it needs to be. If we kept the short 41 centimeter stays the weight bias would be shifted more on the rear wheel and cause the bike to speed wobble once the speeds reached 30+mph. The solution is simple, either lower the rider back down into the uncomfortable position to get more weight bias on the front wheel or increase the length of the chainstays. Also, longer chainstays are more comfortable. They are part of the passive suspension that when combined with a radius formed seat stay no other design can touch.

Our production frames are made one hundred percent out of U.S. titanium and built in Chattanooga, TN. Steelhead Bicycles has partnered with the Chattanooga manufacturers over the years and our retail store, Maplewood Bicycle, continues to be one of the top dealers of Merlin, Litespeed, and Lynskey Bicycle frames in the world. No other frame material comes close. The paint doesn’t chip because there isn’t any. The titanium frame doesn’t crack if the shovel falls off the hook in the garage and smacks your top tube. And titanium doesn’t jar your teeth loose when the roads get rough. We don’t glue or bond any carbon tubes into our frames for sex appeal. It is heavier, weaker, and bound to fail. Nothing beats a perfect Argon purged tig-weld for strength.

Of course we still offer custom frame geometry when it is needed and love the full custom process. It is the reason we started the company to begin with.

Come test ride a Steelhead titanium production bike around our Maplewood Bicycle store in St Louis and experence it for yourself! It is the truth teller about frame compliance. The road alone has sold thousands of frames after our clients. Take the ride and see for yourself!

Get your tri fit nailed the first time!

Our retail shop, Maplewood Bicycle, is known around the world as one of the few places to get your tri fit nailed the first time. We married into the triathlon world hard core decades before triathlon became the huge wonderful sport that it is. With thousands of athletes from beginner age groupers to 40 time Ironman veterans, our intimate relationships over the years in providing fitting and equipment expertise makes us your new best friend.

What makes our triathlon frame better than the competition? First off, triathlons are fast paced and furious and bikes WILL take a fall. Our titanium will take just about anything you can throw at it, or what your competitor might throw at it. Our cable routing is run externally, Shimano specifically states not to run cables internally or it will hinder the shifting performance. If you truly think that cables run inside the frame make you faster than a bike that shifts flawlessly every time and has no hesitation on that critical shift, maybe you should buy the latest magazine bike of the week. Our multisport clients train every single free second they have and that is very hard with a career and a family. We love seeing everyone at the shop but who has a spare hour to blow driving to the shop to get a small tweak on the rear derailleur? We also refuse to design around aero seat posts. The competitions posts slip, crack, fail, creak, and get stuck. If your post breaks on race day, what are the chances the local yocal bike shop will be able to get you going?

Our titanium production frames have the same increase headtube length as our legendary road frame. They are flat out fast and comfortable. You can spend all day in the aero bars and not need the post race emergency massage session so you can look at your computer screen the next day.

We will be posting quite a bit more info on the why’s and why not’s of triathlon fitting and frame design. With our specialty in the fitting process and our intimate knowledge of design, manufacturing, and real shop experience, you will not be disappointed!